IOT - Industrial Remote Equipment Management System (IREMS)

Use Cases

For Industrial/Commerical Purpose

Platform Overview

IOT based Remote Mointor Controller system has ability to control the multiple electronic devices remotely. The system provides intelligent services for users and provides control with Smart Phone devices. The system consist of three types of devices.

Features

Security

Our application is secure, intruders are not allowed to access without the authentication. Secured access even to IOT device is provided as password changes dynamically similarly to OTP.

Predictive Maintenance

Measurement taken by the IOT device are available to the User in a graphical representation that the user can use to analyze the state of the machine at any point in time. It allows to select various measurement parameters to predict potential failures or breakdowns before they occur.

Centralized Monitoring

Enable remote access to machinery data and diagnostic tools through IoT-controlled devices. Allow maintenance technicians to diagnose issues remotely, reducing downtime and minimizing the need for on-site visits. Grant access to users with assigned Equipments that they are responsible for.

Real-time Monitoring and Alerts

Use IoT sensors to monitor machinery health parameters such as temperature, pressure, vibration, and lubrication levels in real-time. Trigger alerts and notifications to maintenance teams or supervisors when any parameter exceeds predefined thresholds, indicating potential issues.

IOT Device Support

IOT device is designed to capature the following measurements:

- Temperature Measurement

- Voltage Measurement

- Current Measurement

- Vibration Measurement

- Pressure Measurement

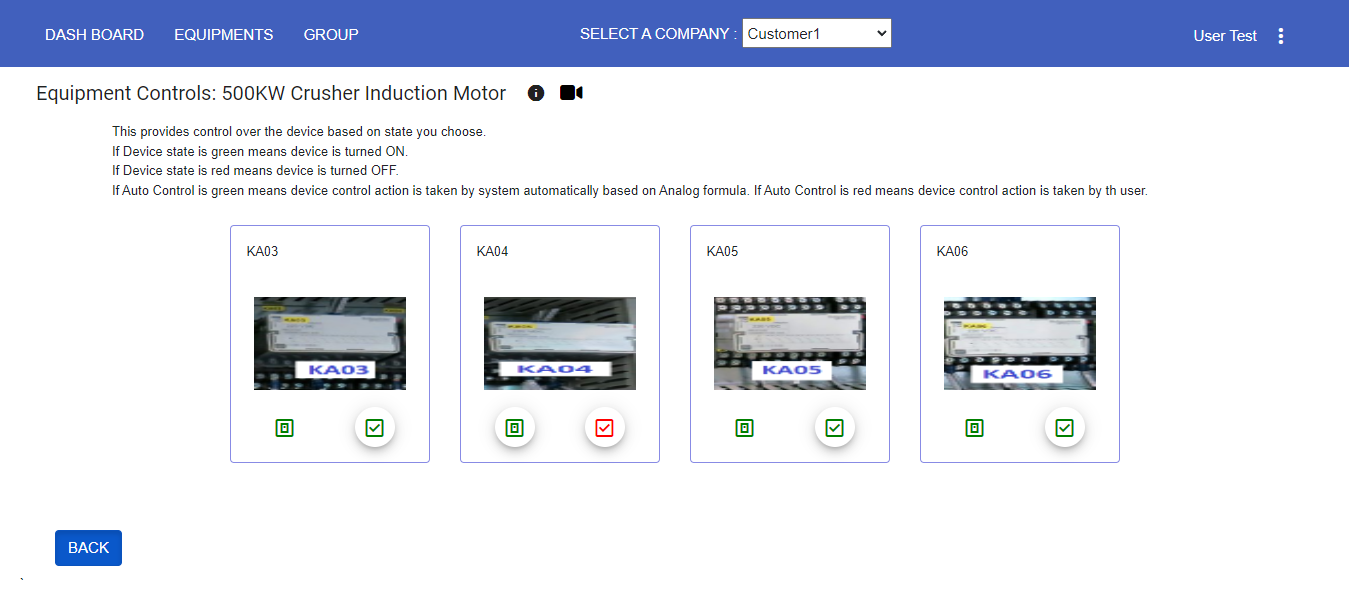

Remote Equipment Control

IOT device is designed to take commands from the Server. Devices that are monitored can be assigned a formula based on the measured parameters. Outcome of these formula are mapped to Control the equipments automatically. Also user can control them manually. Thus allowing control over the Equipments remotely

-

For more Product info please click the below links

On Boarding Process

-

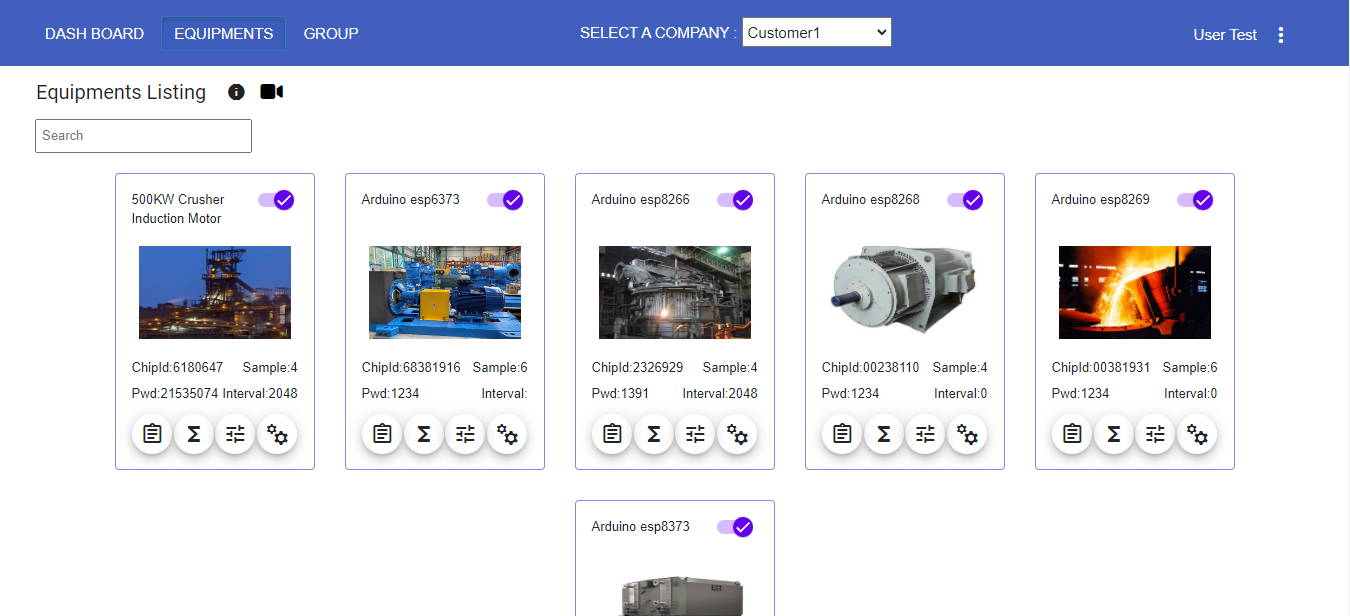

#1 Registration of Device in Factory

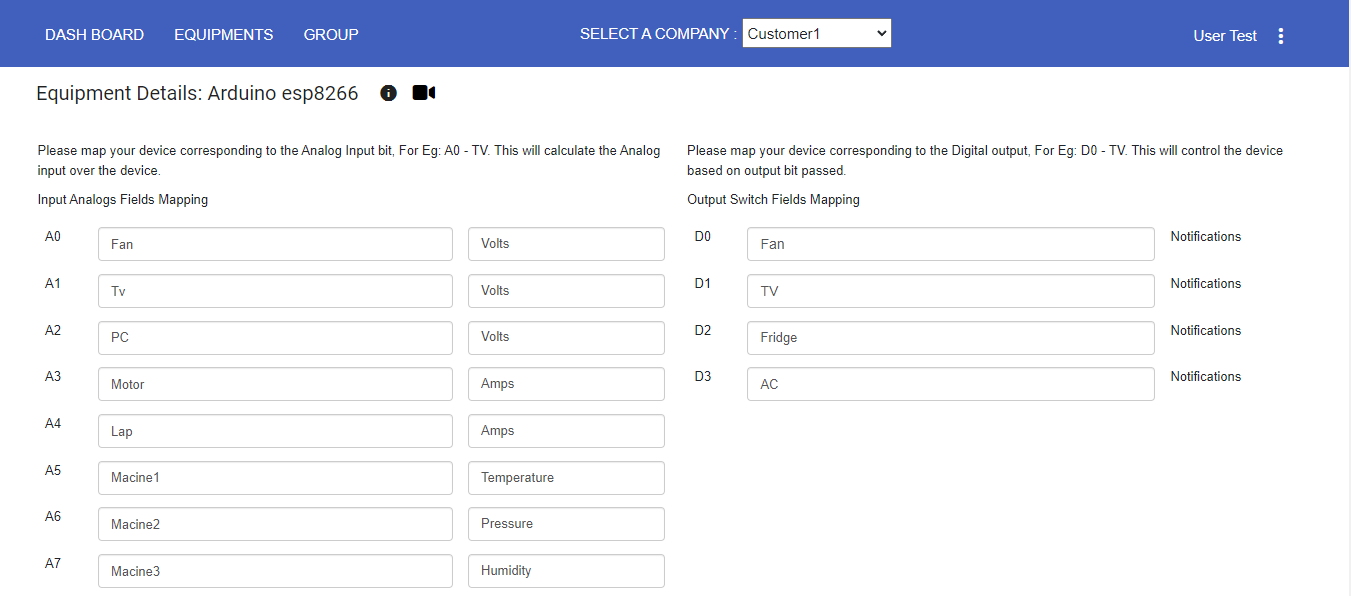

Device Initialization and Registration. Based on device type either 8 or 16 analog inputs are connected to the platform and 4 to 8 devices can be controlled.

-

#2 Installation of Device

Dispatch our service engineers to your place to set controls of the device based on your requirement.

-

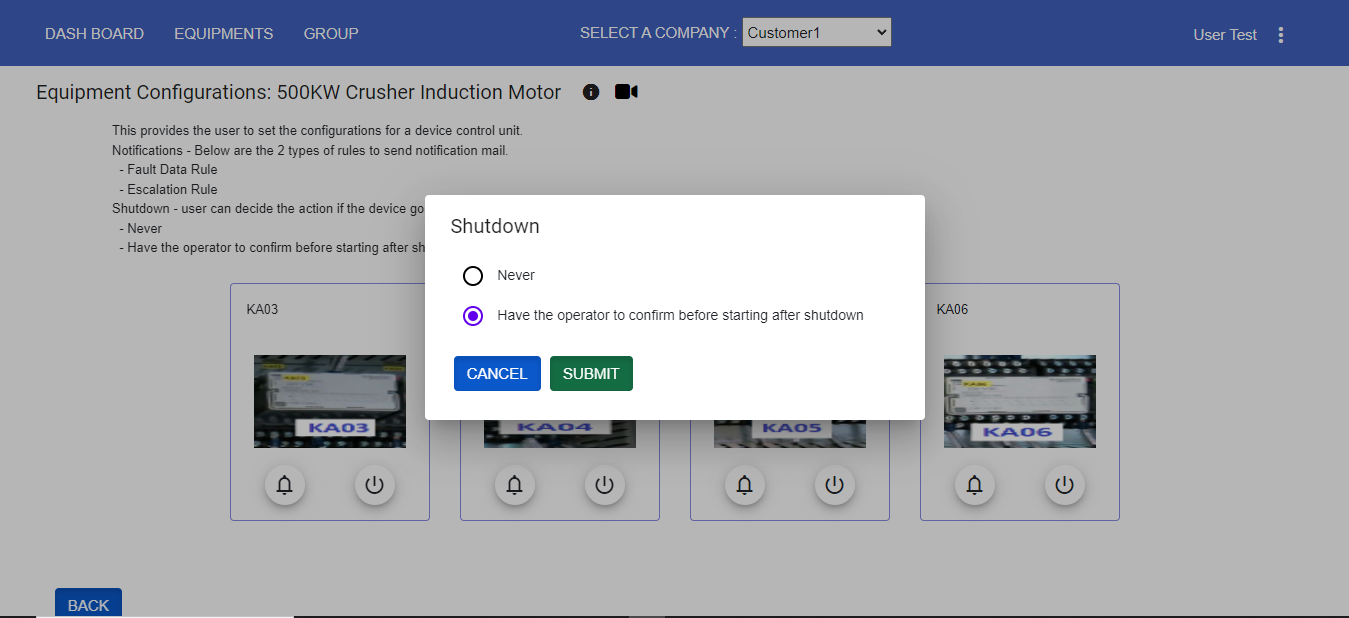

#3 Customization of Device

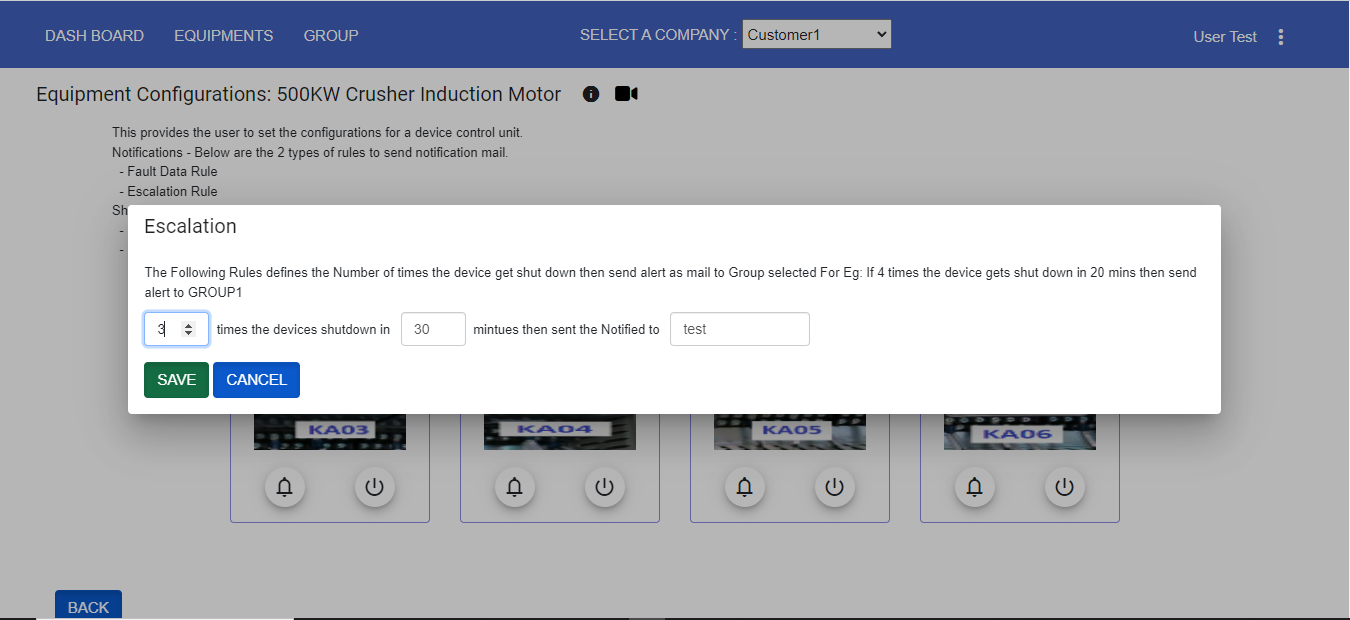

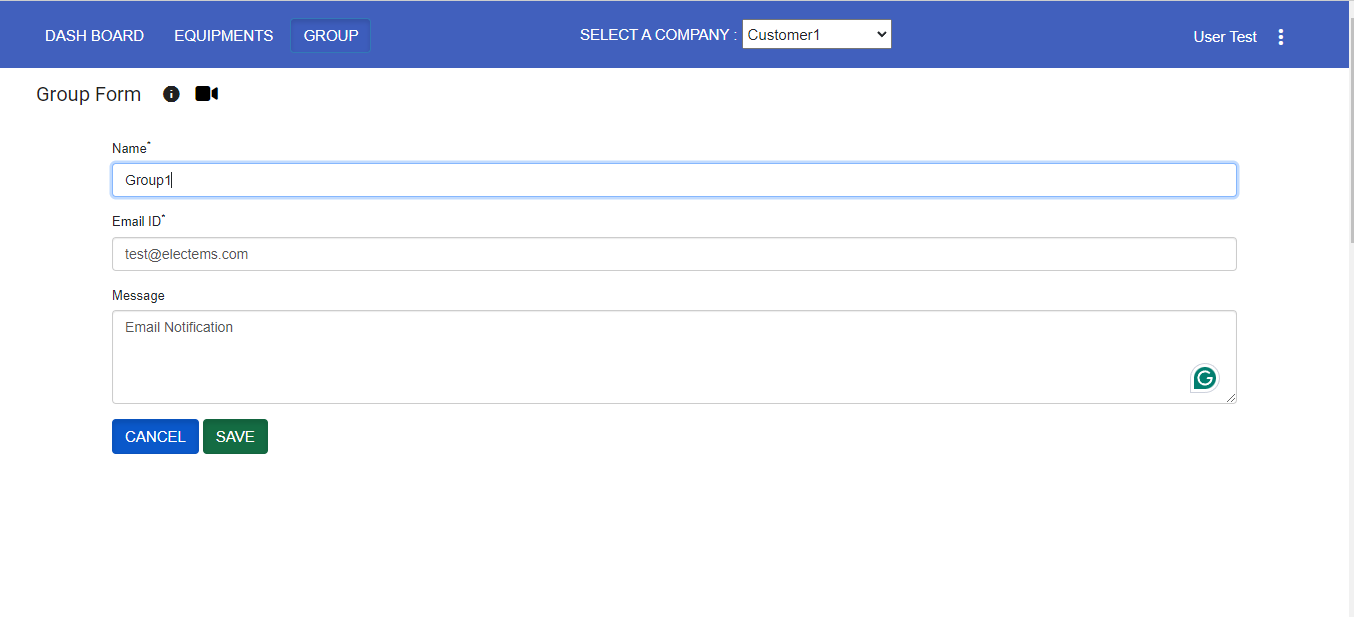

The user has a control to configure the Formula for Device Output based on Analog inputs, by which state of the device is determined which is either ON/OFF and Escalation email can be configured and triggered to Group in case of failures.

-

#4 Monitoring State of Device

The continues Analog reading of each device has been monitored for every X interval of minutes, which will determine the state of the device.

Pricing Plans

Commercial/Industry

- - Device Intialization & Registration ₹12K/device (Single Time)

- - Each device type 1 supports 8 measurements & 8 Appliances

- - Each device type 2 supports 16 measurements & 4 Appliances

- - Will have dedicated Staff managing over the devices

- - Access to the Platform.

- - 5 hours of free support above 5 hours Support at ₹1500/hour

Enterprise

- - Device Intialization & Registration ₹12K/device (Single Time)

- - Multiple Location/Units Support

- - Will have dedicated Staff managing over the devices

- - Access to the Platform.

- - Unlimited support